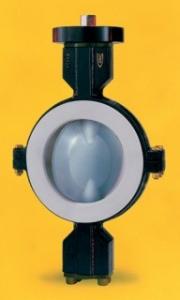

Durco invented the chemical service butterfly valve 45 years ago to handle the demanding requirements of the chemical process industries. The BTV Lined Butterfly Valve is the latest style of such a valve, utilizing all of Durco's accumulated experience. Since the standard valve has a lined body and disc, it is capable of resisting attack from even the most corrosive of chemicals.

Features

• Maintenance free, live loaded, Triple Seal design assures bubble tight shutoff:

• The primary seal is formed at the disc hub by the spherical ball and socket disc/liner seal.

• An independent secondary seal of PTFE-covered convolutions on the disc stem enhances sealing with its tortuous no-leak path design.

• Finally, the O-rings in the alloy gland follower offer added protection from external media corrosion as well as preventing leakage to the atmosphere.

• Assured leak tight sealing by a compression ring which keeps the dynamic pre-load force constant while energizing the various components of the triple shaft seal design

• Never needs adjustment of the dynamic live loaded shaft seal

• Prevents cold flow and facilitates installation with the recessed 1/8" (3 mm) thick (nominal) rigid machined PTFE or UHMWPE liner

• Disc swing is compatible with ASTM F423-82 Flouropolymer lined pipe

• Easily rebuilt because of the ASTM A395 ductile cast iron split body

• Positive valve position indication and simplified adaption to automatic operation due to the Double-D shaft drive

• Interchangeable actuator mounting plate accommodates ISO, MSS or special actuators

• Resists the effect of atmospheric corrosion due to the epoxy coated body and mounting plate

Prev product:No prev product Next product:AKH2 |

Edit Content

Edit Content.jpg)

.gif)

.gif)

.gif)